SUGAR PLUS BLENDS DESERVE TOP-OF-THE-LINE CONTAINERS

That’s why since December 2022, the company Loda di Visano (Bs) exclusively produces their famous fiberglass tanks for Sugar Plus, ensuring optimal product preservation. But for Sugar Plus, the Brescia-based company also provides a meticulous used equipment revision service.

Our livestock customers are well aware that in addition to sugar and organic acid blends, here at Sugar Plus, we also provide them with suitable containers for proper storage and distribution of the product through a loan agreement. We not only ensure timely supply of the mixture but also take care of repairing any potential faults,” Matteo Olini explains clearly and concisely when discussing the proper storage of Sugar Plus liquid feed. It is a delicate topic since only through appropriate storage can the sugary substances contained in Sugar Plus products be correctly mixed into the feed. “The fundamental element,” emphasizes Matteo, “is that for proper storage of our liquid feed, a container is needed that is not only resistant to external weather conditions but also capable of optimally storing the liquid feed inside. From this perspective, fiberglass provides better guarantees compared to polyethylene. That’s why, for the past 16 years, both Sugar Plus and Loda di Visano (Bs) have been in partnership. Loda has become the top choice in the field of fiberglass tanks, thanks to our collaboration with Sugar Plus.” Such is the excellence of the Visano-based company and the harmony between the two companies that since December of last year, Loda has been exclusively producing its fiberglass tanks for Sugar Plus.

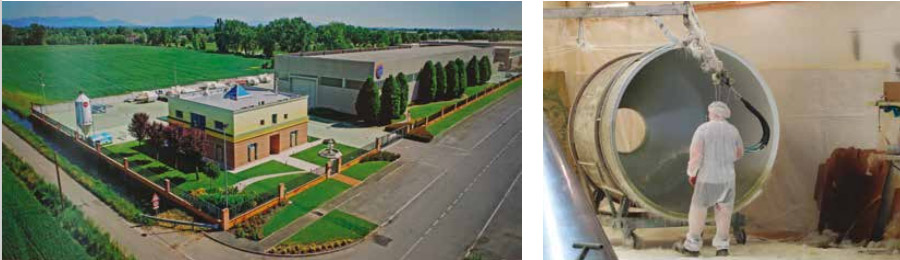

On the left: The Loda company boasts over 40 years of experience in the production of fiberglass tanks.

On the right: Loda, production department: Fiberglass is distributed onto the mold. It is an extremely durable material resistant to the wear caused by weather elements.

Incomparable know-how

And here we are, face to face with Luciano Telefri, the owner of the Brescia-based company along with his brother Orazio. “Our company,” he explains, “is a family-run industry specialized in the construction and shipment of fiberglass silos and tanks, employing 15 employees at the moment. Our strengths? Firstly, our know-how, as my brother Orazio has been working with fiberglass processing for over 40 years. And then, our after-sales support: our products come with a 10-year warranty, but even in case of malfunctioning of a part that is not of our construction, such as a pump or a screw conveyor, we immediately intervene for an immediate solution to the issue. Our customers know this, and that’s why their word-of-mouth recommendation is our best selling tool.” Stepping into the warehouse where the production of fiberglass tanks takes place, well-known and appreciated even abroad, one immediately realizes that everything is organized and implemented to guarantee the highest quality to the finished product.

An example is provided by the multilayer painting of Sugar Plus tanks: externally, the fiberglass casing is painted in green, but internally, there is a layer that prevents the so-called “sweating” of the fiberglass. Then, there is a layer distributed to shield the light, and finally, the white coating that comes into contact with the liquid feed. It is also worth noting that during the assembly of galvanized iron parts – produced by third parties based on Loda and Sugar Plus’ instructions – the continuity of the wall is interrupted, particularly at the drilled holes for bolting the metal supports to the casing. Well, inside the tank, each hole is closed one by one with fiberglass and subsequent layers of painting.

On the left: The Sugar Plus logo is not applied as a sticker but is an integral part of the tank.

On the right: The tank is removed from the mold.

At the top: The metal parts, produced by third-party companies other than Loda, are applied to the tank. The interior of the tank is completely reconstructed at the bolt locations.

Below: Even the metal parts of Sugar Plus tanks are designed to ensure maximum functionality and durability.

Guaranteed Used

There is another aspect that makes the tanks produced by Loda for Sugar Plus special: “To our livestock customers,” Matteo Olini emphasizes, “we usually provide them with brand new tanks or refurbished tanks equipped with new distribution systems, including pumps. This is possible because, thanks to a recent investment plan, Loda is able to provide us with top-notch refurbishment services.” In these cases, the Brescia-based company takes care of everything: they retrieve the tank for refurbishment, perform the necessary cleaning – a non-trivial step that requires specially designated tanks for water decantation – then carry out any necessary repairs, replace the liquid feed distribution system, and finally arrange for shipment to the Sugar Plus customer. “The result of this entire process,” Olini states, “is that we have refurbished tanks that are 15-16 years old but still perfectly functional. This clearly demonstrates the company’s commitment to sustainability by reducing waste and extending the lifespan of the equipment.” “Furthermore,” adds Luciano Telefri, “after the refurbishment, the ten-year warranty restarts, so the used tanks are truly as good as new.” It’s a shame not to acknowledge this fact.

On the left: Sugar Plus currently owns 800 tanks, distributed throughout the national territory.

On the right: When the tank is small in size, Loda company takes care of the delivery using its own means.

Taken from Allevatori Top N. 06-2023